More than 20 years of experience

in the concrete industry,

GPE GROUP © Made With ♥ By “The X Agency”

• Stationary Plants

GPEcan offer the complete range of batching plants starting with a capacity of 10 m³/h up to twinplants reaching an output of 300 m³/h. Since almost 25 years countless concrete producers runningthe famous GPE 120-4/5/6 type. Specially designed forthe extreme climate conditions in the MiddleEast the GPE 120 type is a robust, reliableand high quality batching plant.No matter ifReadymix,Precast,Blocks / Interlocks or Kerbstoneswe have the right solution.

• Mobile Plants

To cover the steadily growing field of mobile batching plants we have tied up with the world widemarket leader in this sector, NISBAU from Germany.Be it seasonal capacity bottlenecks, long-term large construction sites, limited space or just a smalltime window–there are different scenarios for which there is only one solution, the use of a mobilemixing plant. Thanks to a foundation-free installation, the system can be set up, dismantled andrelocated relatively inexpensively within a few days.

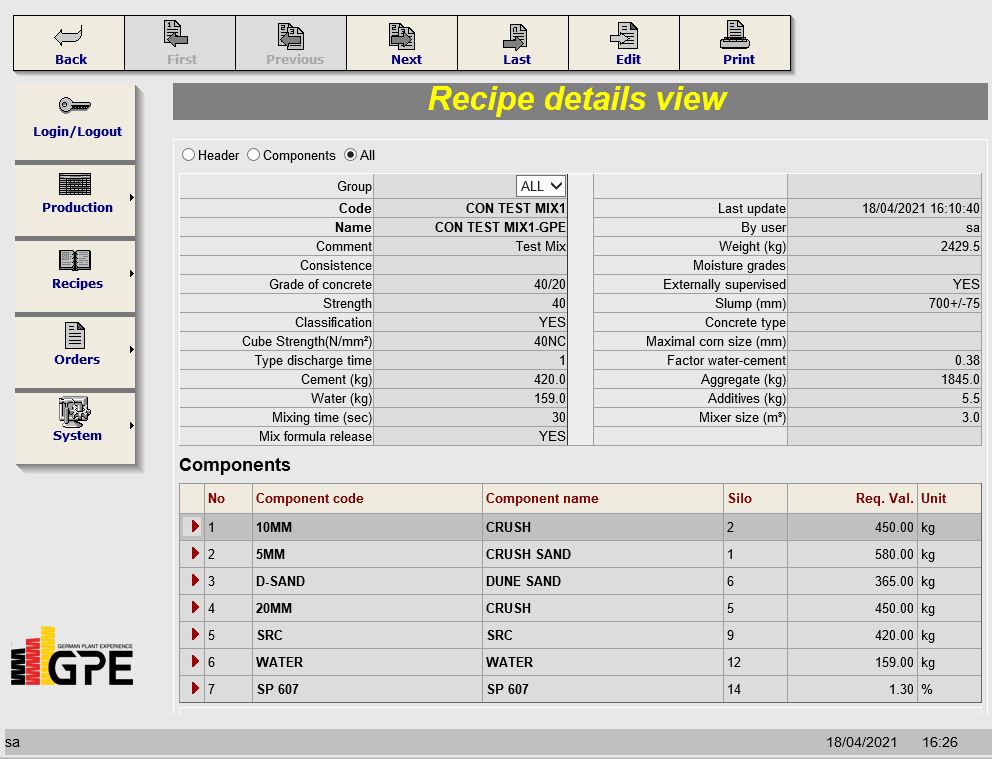

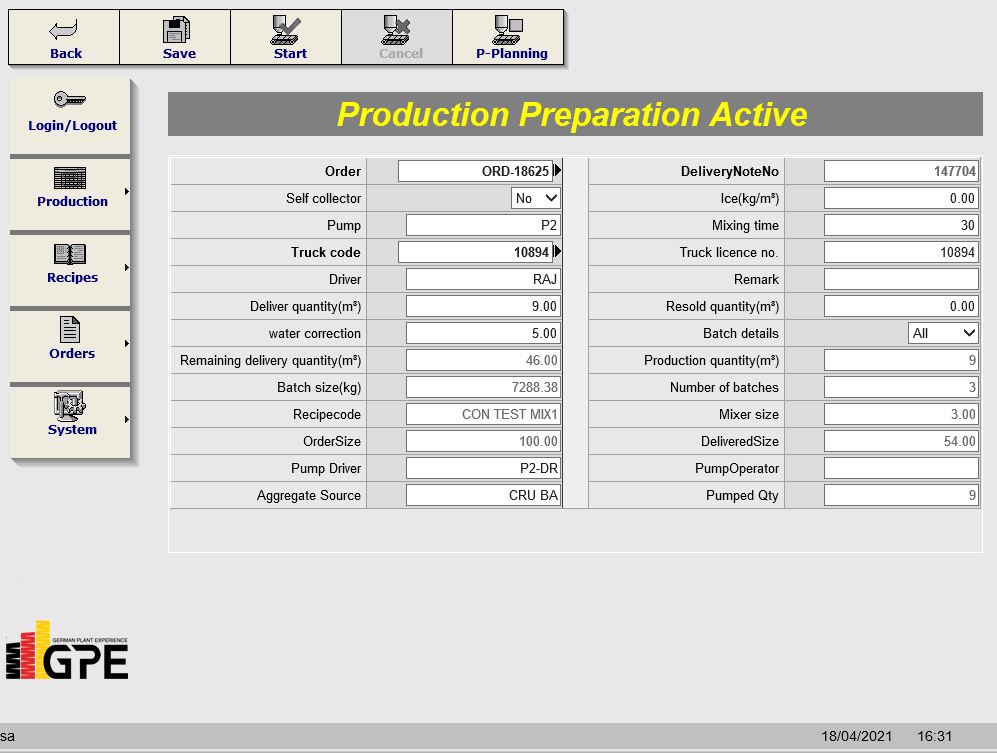

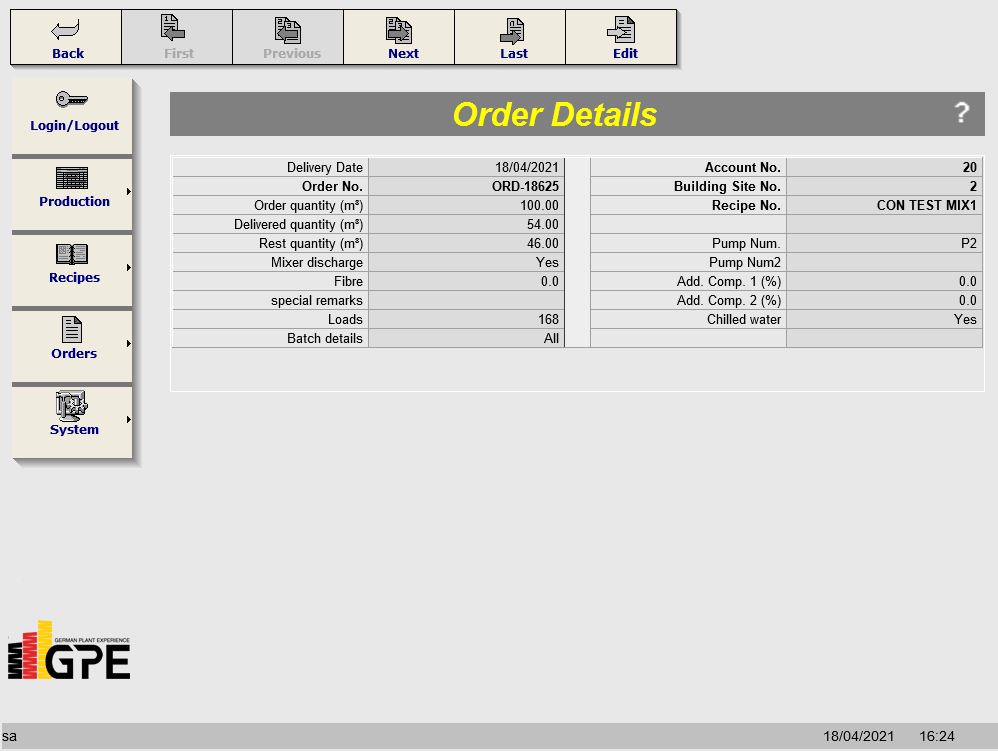

Over decades WEBCon has been developed together with our clients to one of the leading systems in the Middle East. Innumerable projects have been realized with WEBCon througout the region, among them the Burj Khalifa, Dubai Creek Harbour or Hamad International Airport.

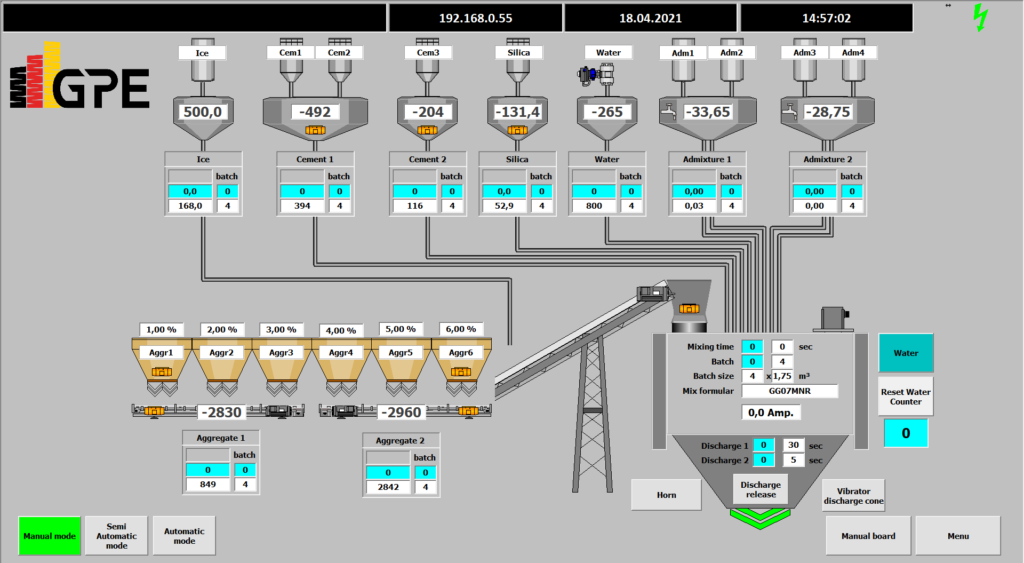

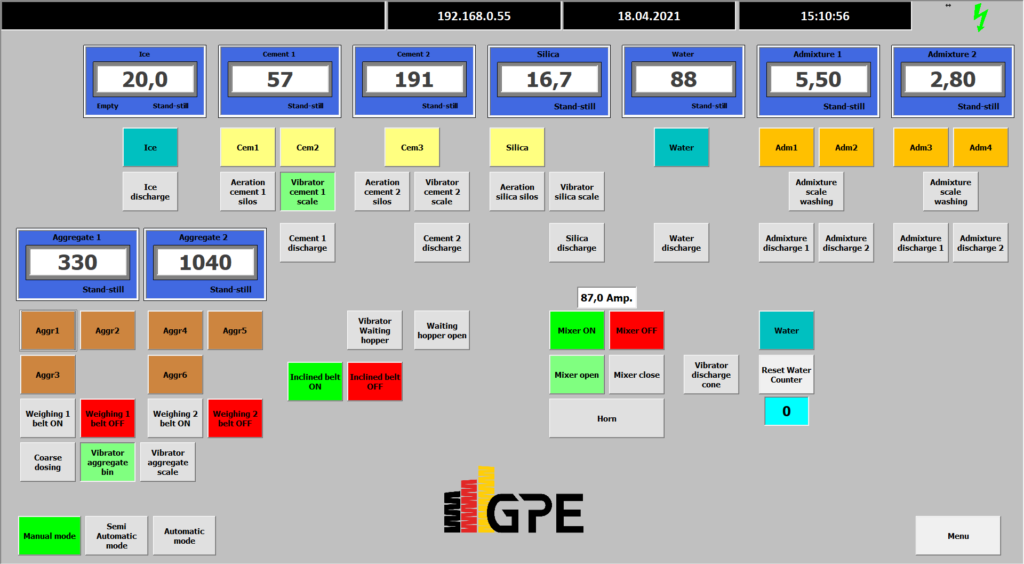

A control system, beside the mixer, is undoubtedly the core component in a batching plant. Absolutely reliable, user-friendly, highly accurate, fully transparent procuction combined with our excellent support and after sales service, this is what all our customers appreciate about WEBCon.

Link all your plants via network

Access your production via Explorer

Alarm messaging via SMS or Email

Preventive maintenance

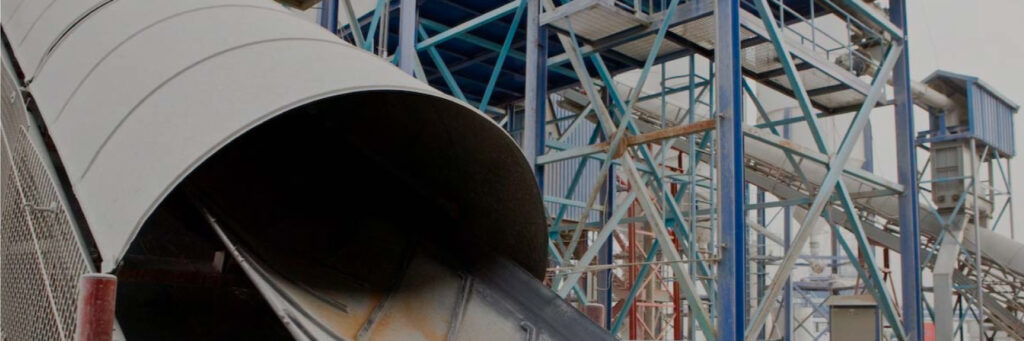

Thanks to our very long experience and our highly skilled and qualified team of technicians we are also widely known for our plant modernizations. Each and every plant component can be overhauled, repaired or replaced.We are converting your old plant into new.

Besides new plants, we offer to our clients also the possibility for plant modernization.

In the photos, you can see a plant before and after our job. Not only we modernized the plant we converted also from dry to wet production.

Cement silos are available in a large range of capacities, from 23 up to 1000m³, and diameters from Ø 2500 up to Ø 9500mm.

No matter if monolithic or bolted silos we have always the right solution.

The screws are available in a wide range of sizes and capacities. They are designed to convey cement and many bulk materials used in batch plants, such as cement, microsilica, gypsum, etc. Housing made of carbon steel complying with UNI 7070-72 standard. Standard sizes are from Ø114mm to Ø323mm with lengths up to 13m. On demand diameters such as Ø407mm, Ø457mm and over.

All types of butterfly valves, silo filters, level indicators and pressure relief valve completing our product range.

Pallett circulation systems, stationary or mobile production sites, with our partner Weckenmann we can provide turn-key solutions for all kind of Precast fabrication.

Our principal BIBKO® has been the leading manufacturer of residual concrete recycling systems with over 1900 systems installed worldwide since 1985.

Our principal BIBKO® is the specialist in the field of residual concrete and wash water treatment in the ready-mixed concrete, precast concrete parts and concrete goods industry.

A BIBKO® recycling system offers the complete solution for recycling residual concrete. With this system, aggregates and water containing cement are recovered and subsequently reused in the production process. This creates an environmentally friendly “zero waste” solution that avoids the problem of residual concrete and wash water disposal. In addition to concrete plants, BIBKO® recycling systems can also be used in mortar and anhydrite plants.

The horizontal shafts with parallel axels, fitted in transmission system with high mechanical performance with epicyclic gearboxes, guarantee an excellent quality in the concrete.

Automatic greasing and washing system are also avaible, as well as lining wear plates in high resistant materials.

All sizes are available.

GPE is exclusive supplier of all types of high quality load cells from selected manufacturers.

Ludwig has been the driving force in the development and production of water dosing and moisture measurement systems for more than 40 years and is one of the leading international companies in this field of application.

Highest quality concrete for nearly all concrete products is the result of this mixer. Rotating and counterflowing mixing stars and arms ensures the best mixing result. Gearbox with hydrodynamic coupling protects against overload and guarantees a long life.

All sizes are available.